Engineered wood flooring has emerged as a versatile and durable option, offering both timeless beauty and practicality. When paired with underfloor heating systems, this dynamic duo provides unparalleled comfort and efficiency in our living spaces. In this detailed guide, we will explore the nuances of installing engineered wood flooring over underfloor heating, revealing the keys to achieving a seamless installation.

Table of Contents

ToggleUnderstanding Underfloor Heating Systems

Before delving into the installation process, it’s essential to grasp the fundamentals of underfloor heating systems. There are two types:

Electric Underfloor Heating:

This system installs electric heating cables or pads beneath the floor surface. When activated, these cables generate heat, which radiates upward through the floor, warming the room above. Electric systems are relatively easier and less expensive to install, making them popular for renovations and smaller spaces.

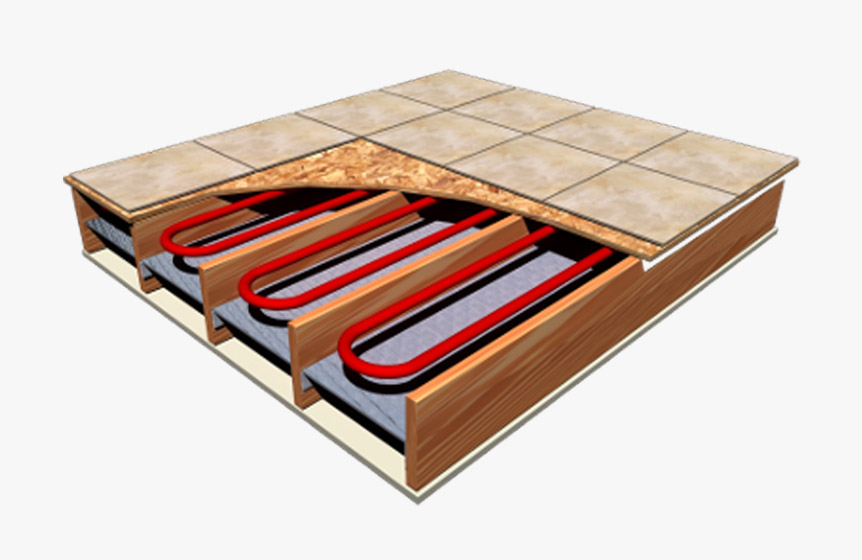

Water-Based (Hydronic) Underfloor Heating:

In this setup, flexible plastic pipes or tubing are positioned beneath the floor, enabling the circulation of warm water from a central boiler or heat pump. This warmth permeates the floor, generating radiant heat that ascends to warm the room overhead. While water-based systems may be more complex and costly to install initially, they offer greater energy efficiency and are often preferred for larger residential or commercial applications.

Preparing for Installation

- Selecting the Right Flooring: Not all types of engineered wood flooring are suitable for use with underfloor heating systems. Choose engineered flooring specifically designed for this purpose, with a low thermal resistance (often referred to as an “R-value”) to allow for efficient heat transfer.

- Acclimation is essential: Let the floor adapt to the temperature and humidity of the environment first. This precautionary step reduces the likelihood of expansion, contraction, or warping when the heating system is activated.

- Subfloor Assessment: Ensure that the subfloor is clean, flat, and dry before laying the engineered flooring. Any irregularities or moisture issues can affect the performance of both the flooring and the heating system.

Installation Techniques

Floating Installation: This method involves laying the engineered wood flooring over a suitable underlayment without attaching it to the subfloor. Floating installations are often recommended for use with underfloor heating systems, as they allow for natural expansion and contraction of the flooring.

In the glue-down installation method, the engineered wood planks are affixed directly to the subfloor using an appropriate flooring adhesive. While glue-down installations can provide a solid and stable surface, it’s essential to choose an adhesive compatible with both the flooring and the heating system.

Nail-down installation, though less frequent in conjunction with underfloor heating, entails fastening the engineered wood planks to the subfloor using nails or staples. Care must be taken to avoid damaging the heating elements or pipes beneath the subfloor during installation.

To mitigate potential moisture concerns associated with hydronic systems, careful consideration of several factors is paramount to ensure optimal outcomes.

There are four primary factors to bear in mind:

- Floor Temperature: The subfloor surface should not exceed 85ºF, with the boiler temperature kept below 110ºF.

- Subfloor Specification: Both plywood and concrete are suitable subfloors, with a combination of both being acceptable. Traditional hydronic systems typically entail placement on a plywood subfloor encased in concrete.

- Heating Tube Installation: Following the placement of tubes and the curing of self-leveling concrete, the system should undergo testing before hardwood installation.

- Climate Controls: Regularly monitor temperatures (as specified above) and ensure humidity levels remain between 30% and 50% to prevent hardwood splitting or gaps.

It’s important to note that engineered wood floors serve as insulators, meaning that while the floor’s heat won’t significantly impact ambient air temperatures, it will provide comfortable warmth underfoot.

Tips for a Successful Installation

Ensure adequate expansion gaps by leaving spaces around the room’s perimeter and at transitions to accommodate the natural movement of the flooring. These gaps accommodate changes in temperature and humidity, reducing the risk of buckling or warping.

- Temperature Settings: Follow the engineered wood flooring manufacturers‘ guidelines for temperature settings and operating procedures to prevent overheating or damage to the flooring. Gradually increase the temperature over time to minimize stress on the flooring materials.

- Regular Maintenance: Once the engineered wood flooring is installed, maintain the underfloor heating system and flooring according to the manufacturer’s recommendations. Regular inspection and maintenance help ensure efficient operation and prolong the lifespan of both the flooring and the heating system.

Conclusion

In conclusion, installing engineered wood flooring over underfloor heating requires meticulous planning, attention to detail, and adherence to best practices. By selecting the right flooring materials, preparing the subfloor properly, and choosing the appropriate installation method, homeowners can create a warm, inviting, and efficient living space that combines the natural beauty of wood with the comfort of radiant heat.

With the proper techniques and maintenance, this dynamic duo will provide years of enjoyment and enhance the aesthetic and functional appeal of any interior space.