Engineered Herringbone Wood Flooring Manufacturer

2. By Custom Size

4. By Installation Loss

By Herringbone engineered

wood floor Species

Oak herringbone engineered flooring

Our oak origins come from Europe and Russia, white and grey herringbone oak wood flooring is widely used in home and business. Crafted from high-quality oak veneers, it offers the classic elegance of herringbone pattern with modern engineering.

Walnut herringbone engineered flooring

Crafted from premium walnut veneers, it boasts rich hues and intricate grain patterns. Our flooring combines the classic herringbone design with engineered durability, providing superior stability, resilience, and easy installation.

Teak herringbone engineered hardwood flooring

Teak herringbone engineered hardwood flooring exudes natural beauty with its golden-brown hues and classic herringbone design. Crafted from high-quality teak wood, it offers exceptional durability and resistance to moisture and wear.

Iroko herringbone engineered wood floor

Crafted from premium Iroko veneers, it radiates warmth and character with its rich color and unique grain patterns. Engineered for superior durability and stability, our flooring offers a timeless herringbone design that enhances any interior with style and sophistication.

Doussie engineered herringbone parquet flooring

Crafted from sustainable Doussie timber, it combines the beauty of hardwood with the durability of engineered construction, ensuring stability and resistance to moisture. Enhance your space with sophistication and eco-consciousness.

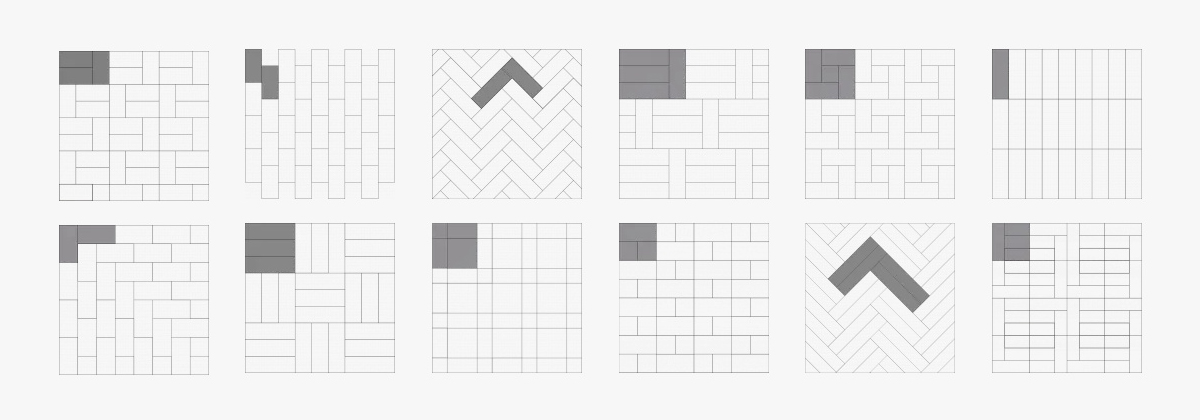

By laying herringbone engineered flooring

- Traditional Herringbone

- Classic and timeless, planks are laid at a 90-degree angle to create a distinctive zigzag pattern, evoking elegance and sophistication.

- Double Herringbone

- Two rows of herringbone patterns are laid side by side, doubling the width of the pattern for a bold and impactful design statement.

- Basketweave

- Planks are laid in alternating directions to form a square or rectangular pattern resembling a woven basket, adding texture and dimension to the floor.

- Mixed Width Herringbone

- Planks of varying widths are used to create a dynamic and eclectic herringbone pattern, adding visual interest and character to the floor.

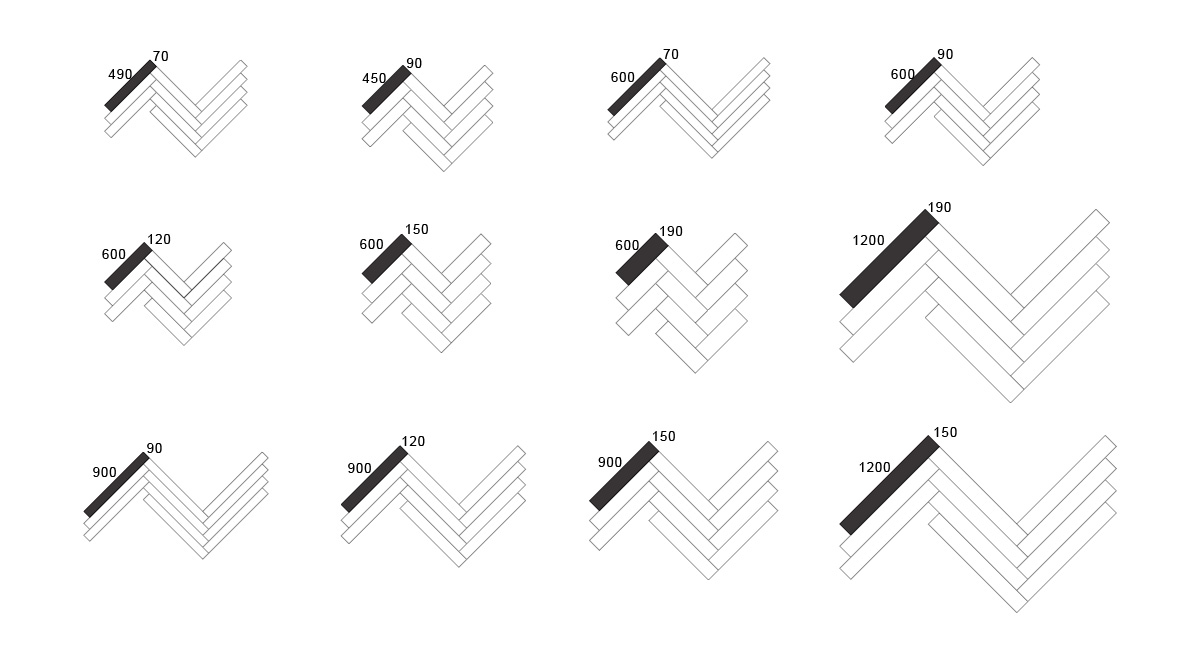

By engineered herringbone parquet flooring size

Installation loss of herringbone engineered wood flooring

To calculate the installation loss for herringbone laying with 90mm x 600mm floorboards in an area of 100 ft², we'll follow these steps:

- Convert 100 ft² to square meters:

- 100 ft² = 100 * 0.092903 = 9.2903 m²

- Calculate the area of one floorboard in square meters:

- Area of one floorboard = (90 mm / 1000) * (600 mm / 1000) = 0.054 m²

- Total area needed ≈ 125 to 130 square feet.

- Determine the number of floorboards required to cover 9.2903 m²:

- Number of floorboards = Total area / Area of one floorboard

- = 9.2903 m² / 0.054 m

- ≈ 172.045 floorboards

- Estimate the installation loss:

- For herringbone laying, the installation loss is typically estimated to be around 5% to 10%. Let's use 5% for this calculation.

- Installation loss = Total area * Percentage loss

- = 9.2903 m² * 0.05

- = 0.4645 m²