Engineered Wood Flooring Structure

Unlike solid hardwood, enginerred wood flooring is composed of multiple layers of wood or a wood composite, arranged in a cross-grain configuration to minimize expansion and contraction.

Comparison Chart

Feature | 2-Layer | 3-Layer | Multi-Layer |

Layers | 2 | 3 | 6~12 |

Total Thickness | 9mm/11mm | 14mm/15mm | 10/12/14/15/18/20mm |

Top Layer Thickness | 3mm/4mm | 3mm/4mm | 1.2mm/2mm/3mm/4mm/6mm |

Top Layer Wood Species | Oak, black walnut, teak, beech, birch, ash, etc. | Oak, walnut, teak, beech, birch, ash, etc. | Oak, walnut, teak, beech, birch, ash, etc. |

Core Layer Wood | Pine | Pine, poplar, etc. | Birch, eucalyptus |

Join System | T&G, 2G/5G click | T&G, 2G/5G click | T&G, 2G/5G click |

3-Layer Engineered Wood Flooring

More versatile in installation methods, including floating installations, due to increased stability.

Suitable for a wider range of environments, including those with more variation in humidity and temperature.

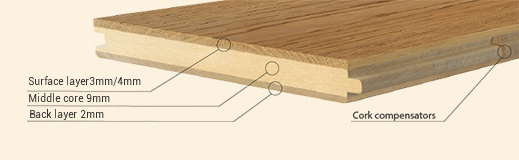

Structure

This flooring is composed of three distinct layers, each made from solid wood veneer, arranged in a staggered lamination pattern.

- The surface layer showcases high-quality whole wood boards selected from an array of species such as oak, walnut, teak, beech, birch, and ash.

- The core layer is comprised of wooden slats made from species like pine and poplar.

- The base of our engineered wood flooring structure is formed from rotary cut veneer, utilizing species such as poplar, birch, and pine.

Thickness

The top layer thickness of enginerred wood flooring should not be too thick or thin, we guaranteed our fabricated engineered wood flooring’s thickness is above 3~4mm, and the totall thickness ranges from 12mm to 20mm.

Multi-Layer Engineered Wood Flooring

It provides the highest stability among the three types, and reduce the wood’s natural expansion and contraction, making it very durable.

Ideal for all areas of the home, including high-moisture areas like kitchens and basements.

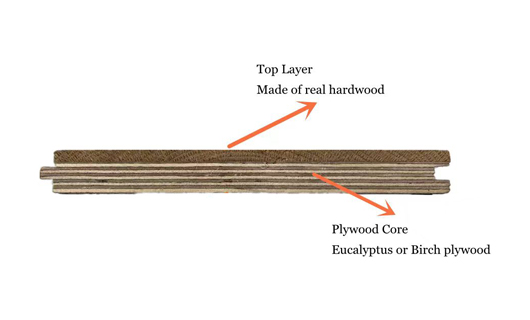

Structure

- The topmost layer is a thin slice of natural 0.5~6mm thickness hardwood. A thicker top layer allows for more refinishing over the lifespan of the floor.

- Beneath the top layer are 6~12 cross-grain configurated core layers, typically made of plywood, HDF (High-Density Fiberboard), or sometimes softwood.

- The bottom layer, often made of hardwood, plywood, or HDF, provides additional stability.

Thickness

- Our top layer thickness is available in a variety of thicknesses, choosing from standard top layer thicknesses of 0.5, 1.2, 2, 3, 4, 6mm or custom option.

- We also offer flexibility in the total thickness of the flooring. Available total thicknesses include 10, 12, 14, 15, 18, 20mm or tailored thickness.

2-Layer Engineered Wood Flooring

Our 2-layer enginerred wood flooring stands out in the international market, it is not subject to anti-dumping duties and is exempt from the 25% Section 301 tariffs.

For importers, it means sourcing 2-layer engineered wood flooring from China could provide a significant cost advantage.

For consumers, it could translate into lower retail prices for high-quality engineered wood flooring, making home renovations or construction projects more affordable.

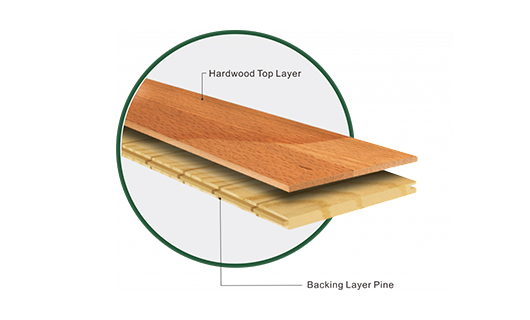

Structure

- Our engineered flooring lies a meticulously crafted two-layer structure, each layer serving a distinct purpose.

- The top layer is adorned with a high-quality precious whole wood panel. It include the timeless elegance of oak, the rich warmth of black walnut, the exotic allure of teak, as well as beech, birch, and ash.

- The base layer is composed of wood slats, typically chosen pine for its reliable durability and structural integrity.

Thickness

- Our 2-layer engineered wood flooring combines a top layer of solid-sawn wood, sourced from the finest Chinese forests, with a thickness ranging between 2-4 mm.

- Beneath this surface layer lies a robust foundation of Chinese pine wood, known for its stability and resilience.

- Finally, our 2-layer engineered wood flooring can have a total thickness of 14-18mm.

FAQ

What is 3-layer engineered wood flooring?

3-layer enginerred wood flooring includes three layers: a hardwood veneer, a core layer, and a backing layer. The core layer is typically made of HDF or plywood, while the backing layer adds further stability.